So many educators have heard the term “21st Century Skills” and lately, it seems the term is being redefined. What used to be word processing, introductory coding, and searching for scholarly articles on the web, has shifted to 3D modeling, PCB fabrication, and coding robots to change the world.

This emphasis on digital fabrication and its involvement in our everyday life can be difficult to implement in the classroom. Most of us haven’t been trained in any of this technology. Below I’ll discuss the basics and talk about some easy (and not so easy) ways to incorporate it into your teaching.

What is digital fabrication?

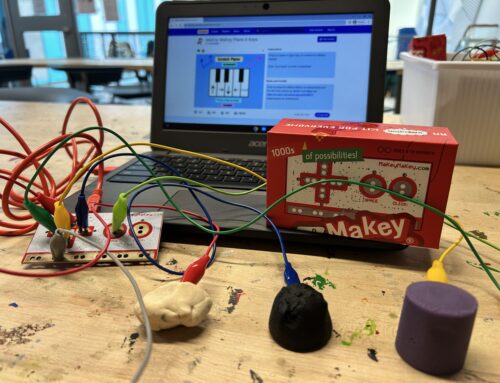

At its core, digital fabrication is “making.” This may involve a variety of processes that could include, but are not limited to coding, 3D modeling, 3D printing, laser cutting, CNC milling, circuit construction, soldering, prototyping, engineering, and PCB fabrication. The push for makerspaces led the way for this new wave, and now even more advanced fabrication laboratories are popping up everywhere.

At its core, digital fabrication is “making.” This may involve a variety of processes that could include, but are not limited to coding, 3D modeling, 3D printing, laser cutting, CNC milling, circuit construction, soldering, prototyping, engineering, and PCB fabrication. The push for makerspaces led the way for this new wave, and now even more advanced fabrication laboratories are popping up everywhere.

Here are some great resources to learn more.

The Alliance for Digital Fabrication Education, a non-profit “formed in an effort to create equality in learning opportunities for young people and promote the development of critical thinking and design entrepreneurship with the use of digital fabrication tools.”

The Fab Foundation, whose goal is to “facilitate and support the growth of the international fab lab network as well as the development of regional capacity-building organizations.”

Why implement digital fabrication in your classroom?

The why of digital fabrication may seem unclear, but it involves the future of our world. There are so many things threatening our society. From climate change causing famine and flooding to antibiotic resistant bacteria threatening another mass extinction, there are so many problems that need solving.

The why of digital fabrication may seem unclear, but it involves the future of our world. There are so many things threatening our society. From climate change causing famine and flooding to antibiotic resistant bacteria threatening another mass extinction, there are so many problems that need solving.

Technological advancement is one way to prepare the next generation for the problems they will face. While it may seem irrelevant now to teach students how to make solar cell phone chargers, that same type of technology may be the solution to a problem down the road. It’s all about arming students with the tools necessary to effect change. Digital fabrication is just one more tool in that toolbox.

How to implement it?

How can we continuously prepare our students for an unlimited number of advancing technologies for which we ourselves are unprepared? Well, there are a million ways to implement digital fabrication into your classroom. I will give a variety of broader examples that can hopefully apply to any classroom anywhere with any budget.

However, if it seems I’ve given you nothing to go on, get online and find your own! The links listed above, and their associated hashtags on Twitter can be a great resource for finding materials. Additionally, many universities are looking for teachers who will implement lesson plans they’ve made. Check with your local college’s engineering education department to see if they can help.

Step 1: Baseline Integration.

The first step in implementing digital fabrication is to simply show students what can be done. While this doesn’t necessarily give them the skills, it exposes them to the technology. Here are some ideas to get you started.

- Show students a video of something being 3D printed, laser-cut, or milled on a giant CNC machine (search any of that on YouTube search and you’ll find some crazy videos!).

- If you have access or can gain access to a 3D printer, print something out to show your students. Just holding a product of this technology can spark an idea or sense of wonder that could change that student’s life.

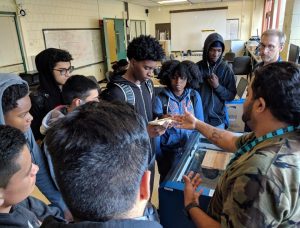

- Ask someone who works in digital fabrication to visit your classroom and bring in some cool stuff. That can be anyone from plumbers and carpenters to engineers! This technology is everywhere. Go find it!

Step 2: Take It to the Next Level.

If you have access to the technology (and time), give your kids a day or five to mess around on tinkerCAD. This is a 3D modeling website that is extremely accessible. All ages can enjoy creating and exploring things that have already been created. There are also a TON of tutorials that anyone can use to learn more. As they say on their website, “No experience preferred!”

Going above and beyond

If you have access or can gain access to digital fabrication machines (through a university or a fab lab in your area), have time in your curriculum, and you’re ready to go above and beyond, then have your kids make! Give them a problem to solve or let them roam free to create whatever they want. They say “the best way to learn is by doing,” and digital fabrication is the pinnacle of this old adage.

I recommend starting small, but if students have big ideas let them run with them. From stickers for their phones, to hydraulic lifts for friends in wheelchairs, the sky’s the limit for this technology.

You’ve got this!

Leave A Comment